The Power of Ultraviolet Inks in Modern Printing Services

In today’s fast-paced business environment, where quality meets efficiency, the printing industry is at a pivotal point of transformation. One of the most significant advancements in this sector is the advent of ultraviolet inks. These innovative inks are crucial in enhancing the printing process, providing businesses with a competitive edge in various applications. This article delves into the intricacies of ultraviolet inks, their benefits, applications, and why they are essential for printing services offered by bostonindustrialsolutions.com.

What Are Ultraviolet Inks?

Ultraviolet inks are specialized inks that dry or cure when exposed to ultraviolet light. Unlike conventional inks that rely on evaporation to dry, ultraviolet inks are made up of photoinitiators which react to UV light. This chemistry results in a fast curing process that offers numerous advantages over traditional inks.

- Immediate Drying: UV inks cure almost instantly upon exposure to UV light, eliminating smudging and allowing for immediate handling.

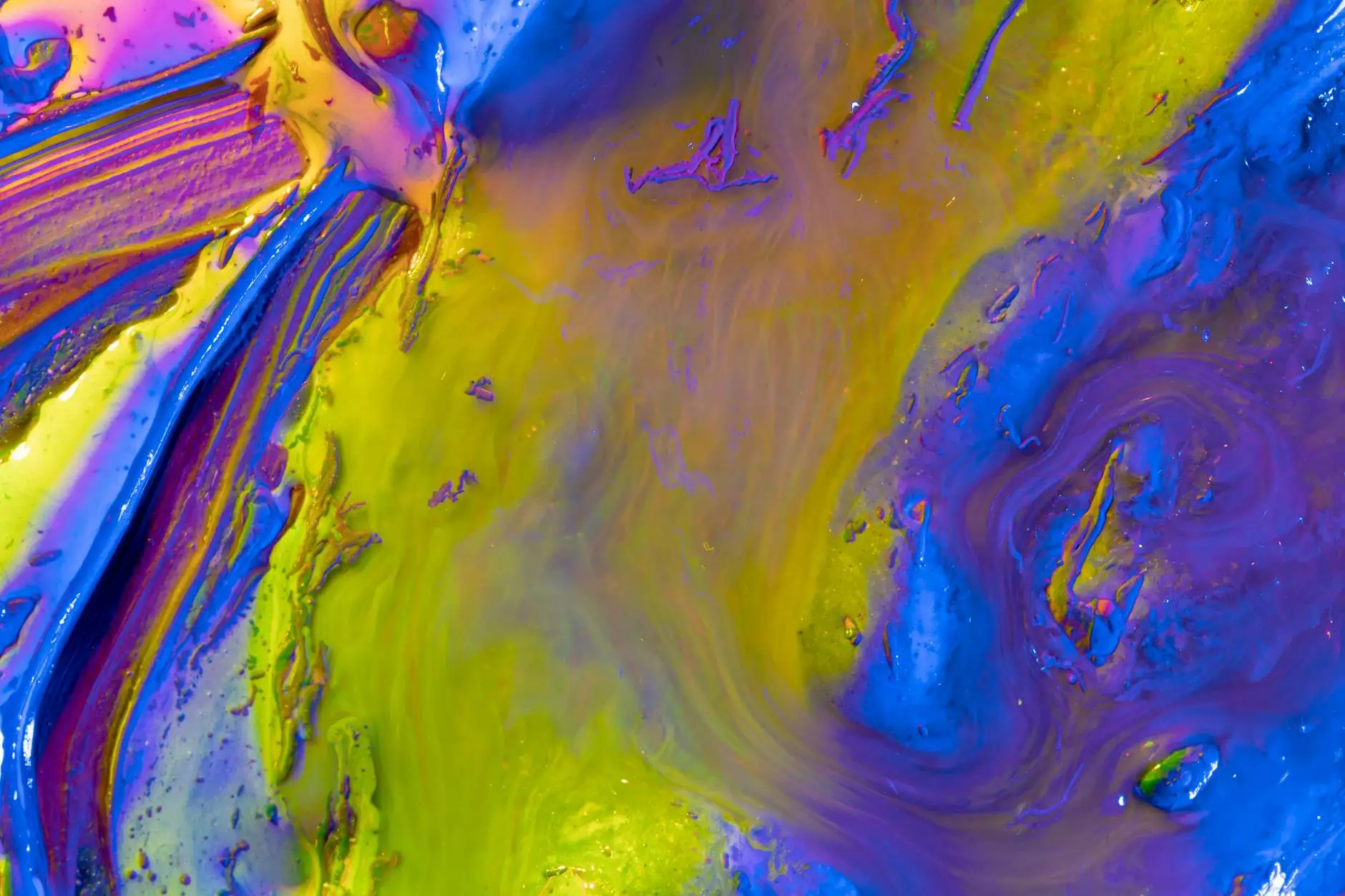

- Vivid Colors: These inks provide brighter and more vibrant colors that can elevate the aesthetics of any print material.

- Durability: UV-cured prints are more resistant to scratching and fading, making them suitable for both indoor and outdoor applications.

- Environmentally Friendly: Many UV inks are free from volatile organic compounds (VOCs), which contributes to a more sustainable printing process.

The Advantages of Using Ultraviolet Inks

Incorporating ultraviolet inks into printing services offers a myriad of benefits that significantly enhance productivity and results. Here are some key advantages:

1. Enhanced Print Quality

One of the most significant benefits of UV inks is their ability to produce high-resolution prints with exceptional clarity. The quick curing process locks in colors and details, resulting in sharp, vibrant images that stand out.

2. Versatility in Substrates

UV inks can adhere to a wide range of materials, including plastics, metals, glass, wood, and more. This versatility opens up limitless possibilities for creative applications, making them ideal for promotional materials, packaging, and more.

3. Cost Efficiency

Although the initial investment in UV printing technology may be higher, the long-term savings are significant. The fast curing times lead to increased production speeds and lower labor costs, making UV printing a cost-effective solution over time.

4. Reduced Waste

Since UV inks dry immediately, there is less risk of ink splashes and misprints, which reduces waste. Companies can effectively manage their materials, leading to a more sustainable approach in printing services.

5. Health and Safety Benefits

Due to lower levels of VOCs in many UV inks, the health risks associated with inhaling fumes are significantly diminished. This creates a safer working environment for employees who handle these inks and operate printing machinery.

The Applications of Ultraviolet Inks

As industries evolve, the applications for ultraviolet inks continue to expand, making them a valuable resource in various sectors:

- Packaging: UV inks are extensively used in the packaging industry, providing attractive, eye-catching designs while ensuring durability.

- Commercial Printing: Businesses utilize UV inks for producing brochures, business cards, and flyers, enhancing their brand visibility and appeal.

- Labels: UV printing allows for high-quality, water-resistant labels that withstand rough handling and challenging environments.

- Textiles: The textile industry benefits from UV inks by providing vibrant prints on garments that are both durable and visually appealing.

- Signage: Outdoor signage produced with UV inks is resistant to fading and damage from UV exposure, ensuring long-lasting quality.

The Future of Ultraviolet Inks in the Printing Industry

With the continuous advancements in technology, the future of ultraviolet inks looks promising. Here are some trends anticipated to shape their evolution:

1. Greater Sustainability Initiatives

As eco-consciousness rises among consumers and businesses alike, the demand for environmentally friendly printing solutions will continue to drive innovation in UV ink formulations. Manufacturers are focusing on developing inks that utilize renewable resources and minimize environmental impact.

2. Technological Integration

The integration of UV printing technology with digital printing processes will enable companies to produce short runs with quick turnaround times, meeting the dynamic needs of their clients.

3. Expansion in Market Applications

As manufacturing becomes more specialized, UV inks are anticipated to penetrate new markets, including automotive, aerospace, and more, providing further opportunities for growth.

Conclusion

Overall, ultraviolet inks have transformed the landscape of printing services, elevating quality and efficiency to new heights. By adopting these inks, businesses can not only boost their print quality but also optimize their operations for greater sustainability and cost savings. As we move into the future, the potential of these inks will only grow, making them a vital component of modern printing solutions.

For companies looking to enhance their printing capabilities, understanding the intricacies and advantages of ultraviolet inks is essential. At Boston Industrial Solutions, we’re committed to providing exemplary printing services that leverage the best in technology for superior results. Explore the possibilities with UV inks today and elevate your business to the next level!